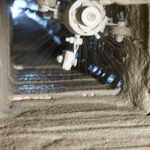

Improve the operation of your fireplace and increase the safety of your home. Smoktite® is a highly insulative ceramic product that is used to seal, smooth and insulate chimney smoke chambers without removing the damper frame or adjacent brickwork. Smoktite® sprays on to seal the surface with a durable ceramic coating that is good up to 2291 degrees Fahrenheit and is impervious to acids, vapors, and water. Introduced in the summer of 2002, Smoktite® is now being used by chimney professionals all across the country.

Why Smoktite®?

The smoke chamber is a commonly overlooked chimney area that is the source of a high percentage of chimney fires. With Smoktite®, chimney professionals can now seal smoke chambers through a process that is faster, easier and more cost effective.

Product highlights:

- Increases the safety of a home, improves the operation of the fireplace, and protects the smoke chamber.

- Repairs damage easily, without the removal of the damper frame and adjacent brickwork — no more hand-troweling!

- The Smoktite® system is lightweight and portable enough to be in every chimney professional’s service truck.

Shop Smoktite®

Transform your chimney with Smoktite® and enjoy the peace of mind that comes with a safer, more efficient, and longer-lasting fireplace. Smoktite® is exclusively available for professional use by factory-authorized chimney sweeps, repair technicians, and fireplace installers.

Get to those hard to reach areas

Get to those hard to reach areas

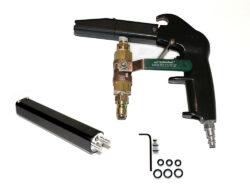

Get to those hard to reach areas with ease with our “Extender” model spray gun, a component system that can be extended in length by 6" increments that will reach virtually any part of any sized smoke chamber.

- The Extender comes in sleek, professional machined components for a maintenance free fit.

- Can be used in multiple lengths.

- Reaches hard to access areas without removing the damper and/or the surrounding masonry.

- Eliminates the need for demolition.

- Our Angle Adapter components (available in 30o and 60o angles) can even help you work around corners

What equipment do I need to use Smoktite®?

You’ll need a compressor with a regulator that’s rated at a minimum of 5 SCFM @ 90 PSI , a ½-inch drill with a mixing paddle and cold water. Water is used to mix the Smoktite® and to clean up.

What preparation of the smoke chamber is required prior to application?

A thorough brushing and/or rotary cleaning will usually suffice.

Does the equipment clean up easily?

Yes! Clean up with water is easy when done promptly after each use.

Once mixed, how long do I have to use it?

The average pot life is about one hour but varies with weather conditions.

Has it been tested?

Yes! It has been tested to 2291°F. It is a highly insulative and lightweight agglomerate.

What kind of coverage will I get with Smoktite?

One bucket will cover approximately 10 square feet at 1/2 inch thick.

How many coats does it take to complete a smoke chamber?

Usually, one to two coats. Additional coats may be necessary for severe problems.

How long do I have to wait between coats?

If multiple coats are necessary, approximately 10-15 minutes is recommended. This is variable depending on temperature and humidity.

Will it seal holes?

Yes! It can seal holes up to 1 inch with a little effort.

How does Smoktite® compare to other products and methods?

Smoktite® is the original spray system for smoke chambers! Our high quality equipment is designed specifically for spraying Smoktite® material not just off the shelf. The gun components are CNC machined in house to exact specifications for our particle sizes. Being a sprayed ceramic, Smoktite® is quick and easy to apply making it more cost effective than traditional parging methods.