Frequently Asked Smoktite® Questions

What equipment do I need to use Smoktite®?

You’ll need a compressor with a regulator that’s rated at a minimum of 5 SCFM @ 90 PSI , a ½-inch drill with a mixing paddle and cold water. Water is used to mix the Smoktite® and to clean up.

What preparation of the smoke chamber is required prior to application?

A thorough brushing and/or rotary cleaning will usually suffice.

Does the equipment clean up easily?

Yes! Clean up with water is easy when done promptly after each use.

Once mixed, how long do I have to use it?

The average pot life is about one hour but varies with weather conditions.

Has it been tested?

Yes! It has been tested to 2291°F. It is a highly insulative and lightweight agglomerate.

What kind of coverage will I get with Smoktite?

One bucket will cover approximately 10 square feet at 1/2 inch thick.

How many coats does it take to complete a smoke chamber?

Usually, one to two coats. Additional coats may be necessary for severe problems.

How long do I have to wait between coats?

If multiple coats are necessary, approximately 10-15 minutes is recommended. This is variable depending on temperature and humidity.

Will it seal holes?

Yes! It can seal holes up to 1 inch with a little effort.

How does Smoktite® compare to other products and methods?

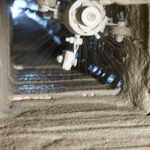

Smoktite® is the original spray system for smoke chambers! Our high quality equipment is designed specifically for spraying Smoktite® material not just off the shelf. The gun components are CNC machined in house to exact specifications for our particle sizes. Being a sprayed ceramic, Smoktite® is quick and easy to apply making it more cost effective than traditional parging methods.